quality control

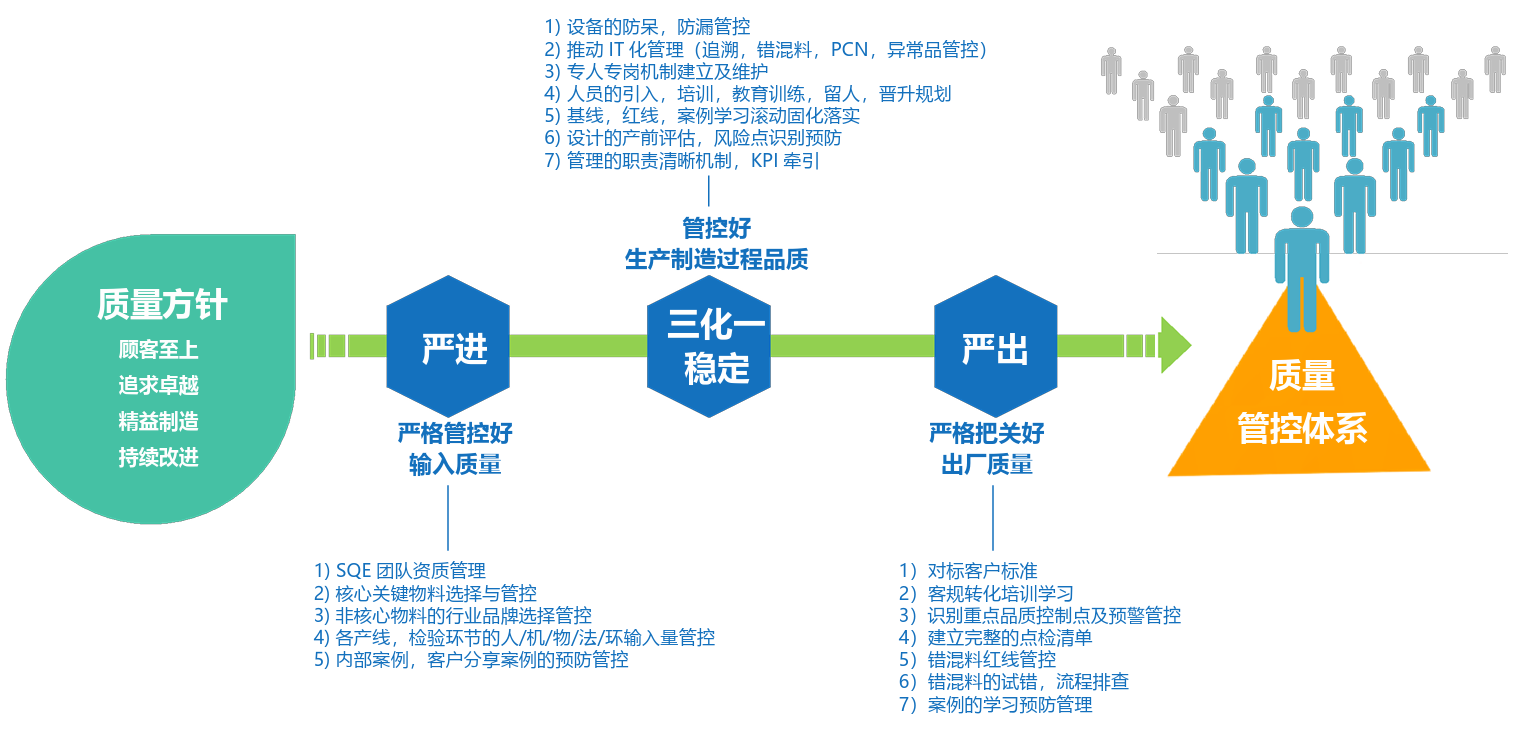

Employees from Konka adhering to the spirit of "take responsibility for the innovative development, open collaboration, diligent and pragmatic", the quality policy of "customer first, the pursuit of excellence, lean manufacturing, continuous improvement", strict entry, strict exit, three and one stable (management IT, production automation, personnel specialization, key positions stable) quality management model. quality management mode (management IT, production automation, personnel specialisation, key positions stability), full lean manufacturing, full quality management.

Management Technology

Advanced Product Quality Planning (APQP)

By fully understanding and digesting customer needs, designing a comprehensive and systematic product processing route and method, tracking and evaluating samples, trial production, and batch production products, continuously revising and improving the control plan for the entire production process, the company aims to comprehensively meet customer requirements for the products processed.

Production Part Approval Procedure (PPAP)

Through this program, it is determined whether all requirements of customer engineering design records and specifications have been correctly understood, and whether the production process has the potential to meet customer requirements in the actual production process at the specified production pace.。

Potential Failure Mode and Effects Analysis (FMEA)

By analyzing various possible failure modes and effects throughout the production process, and based on the specific situation of each failure mode, specific methods for controlling each failure mode are determined, and the control effect is tracked to ensure the stable improvement of product quality.

Statistical Process Control (SPC)

By statistically analyzing the production process parameters and some product characteristic parameters, and drawing control charts for observation, analyzing the trend of the graphics, and making timely adjustments when abnormalities are found to ensure the stability of product quality.

Measurement System Analysis (MSA)

By analyzing the stability, repeatability, reproducibility, and other aspects of the measurement system used for production control, a suitable measurement monitoring system is selected to ensure complete control of the production process.

Quality Control Circle (QCC)

Motivate employees, encourage them to consciously and proactively analyze on-site problems, develop improvement measures, consolidate the results of improvement, commend their proactive spirit, and create a good working atmosphere.

Customer Service

Putting customers at the center, we strive to create inspiration and professional excellence through management mechanisms, corporate culture, and institutional guarantees.